The Ultimate Guide to Non Slip Surfacing Concrete

Introduction

Welcome to NDClean, your trusted source for home services, office cleaning, and carpet cleaning. In this comprehensive guide, we will provide you with all the information you need to know about non slip surfacing for concrete surfaces. Whether you have a residential or commercial property, ensuring the safety of your floors is paramount. Read on to discover the benefits, installation process, and maintenance tips for achieving a non slip surfacing on your concrete floors.

Why Choose Non Slip Surfacing?

Non slip surfacing for concrete is vital for the safety of your family, employees, and customers. Slippery floors pose a significant risk and can lead to injuries, lawsuits, and financial liabilities. By choosing non slip surfacing, you create a secure environment and minimize the chances of accidents caused by slippery surfaces.

The Benefits of Non Slip Surfacing Concrete

Installing non slip surfacing on your concrete floors offers numerous advantages:

- Enhanced Safety: Non slip coatings provide an extra layer of grip, reducing the risk of slips and falls.

- Increased Durability: Non slip coatings protect your concrete surfaces from wear and tear, extending their lifespan.

- Easy Maintenance: Non slip surfacing makes your floors easier to clean and maintain, saving you time and effort.

- Improved Aesthetics: With a variety of colors and finishes available, non slip surfacing can enhance the visual appeal of your concrete floors.

The Installation Process

When it comes to installing non slip surfacing on your concrete floors, it is recommended to hire professionals like NDClean who specialize in this area. Here's a step-by-step overview of the installation process:

- Surface Preparation: The concrete floor is thoroughly cleaned and any existing coating or debris is removed.

- Priming: A primer is applied to enhance adhesion between the concrete and the non slip coating.

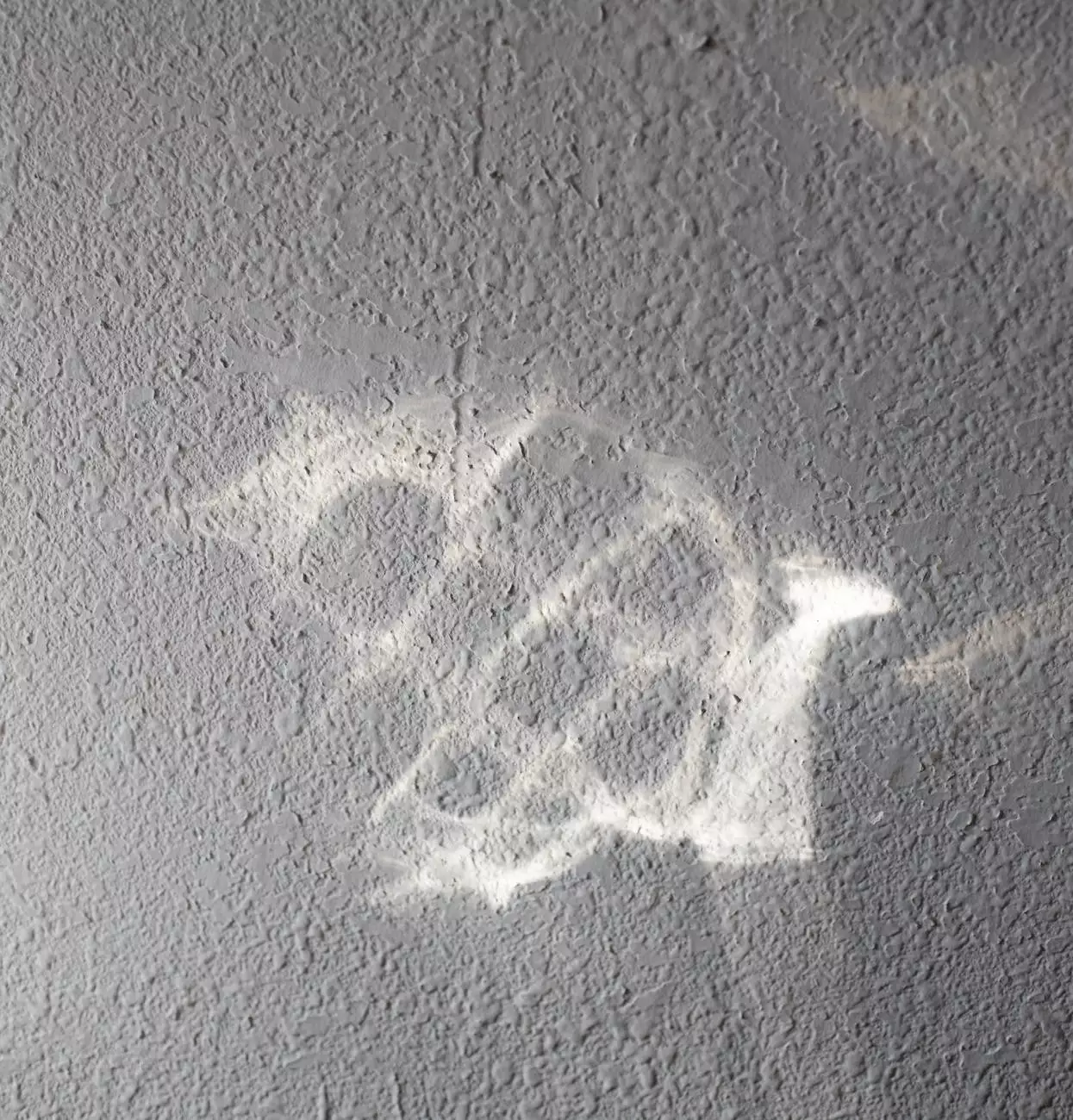

- Coating Application: The non slip coating is carefully applied using specialized tools to achieve an even and durable surface.

- Drying and Curing: The coated surface is left to dry and cure according to the manufacturer's instructions.

- Quality Check: The final surface is inspected to ensure proper adhesion and an evenly distributed non slip texture.

Maintenance Tips for Non Slip Surfacing

To maximize the lifespan and effectiveness of your non slip surfacing, consider the following maintenance tips:

- Regular Cleaning: Clean your non slip coated floors regularly using a gentle cleanser and avoid abrasive cleaning materials.

- Prompt Repairs: If you notice any damages or wear, address them promptly to prevent further deterioration.

- Avoid Harsh Chemicals: Use only recommended cleaning products that are safe for non slip surfaces.

- Periodic Reapplication: Depending on usage and foot traffic, you may need to reapply the non slip coating every few years.

Conclusion

Investing in non slip surfacing for your concrete floors is a wise decision that prioritizes safety and aesthetics. By choosing NDClean, you can trust our expertise in providing excellent home services, office cleaning, and carpet cleaning. Contact us today to discuss your non slip surfacing needs and ensure a secure environment for your property. Remember, the safety of your floors is our top priority!