The Power of Plastic Rapid Prototypes Factory: A Game Changer for Metal Fabricators

When it comes to the manufacturing industry, innovation and precision play pivotal roles in defining success. Metal fabricators around the globe are constantly seeking ways to streamline their processes, reduce costs, and enhance efficiency. This is where the concept of plastic rapid prototypes factory comes into play.

The Evolution of Rapid Prototyping

Rapid prototyping has revolutionized the way products are developed and brought to market. In the competitive landscape of metal fabrication, the ability to quickly create and test prototypes can make a significant difference in time-to-market and overall project success.

Benefits of Plastic Rapid Prototypes

DeepMould, a leading name in Metal Fabricators, has embraced the concept of plastic rapid prototypes factory, offering a wide range of benefits for businesses looking to stay ahead of the curve:

- Accelerated Product Development: By utilizing plastic rapid prototypes, metal fabricators can significantly shorten their product development cycles, allowing for quicker iterations and improvements.

- Cost-Effective Testing: Prototyping in plastic is a cost-effective method for testing product designs and functionalities before investing in full-scale production.

- Customization and Flexibility: With rapid prototypes, metal fabricators have the flexibility to make quick design changes and customize products to meet specific client requirements.

- Enhanced Collaboration: The ability to physically hold and assess a prototype enhances collaboration among team members, clients, and stakeholders, leading to better communication and understanding.

Why Choose DeepMould for Plastic Rapid Prototypes Factory?

DeepMould's commitment to excellence and innovation sets it apart in the world of Metal Fabricators. With state-of-the-art technology, skilled personnel, and a customer-centric approach, DeepMould offers a seamless and reliable experience for businesses looking to leverage the power of plastic rapid prototypes.

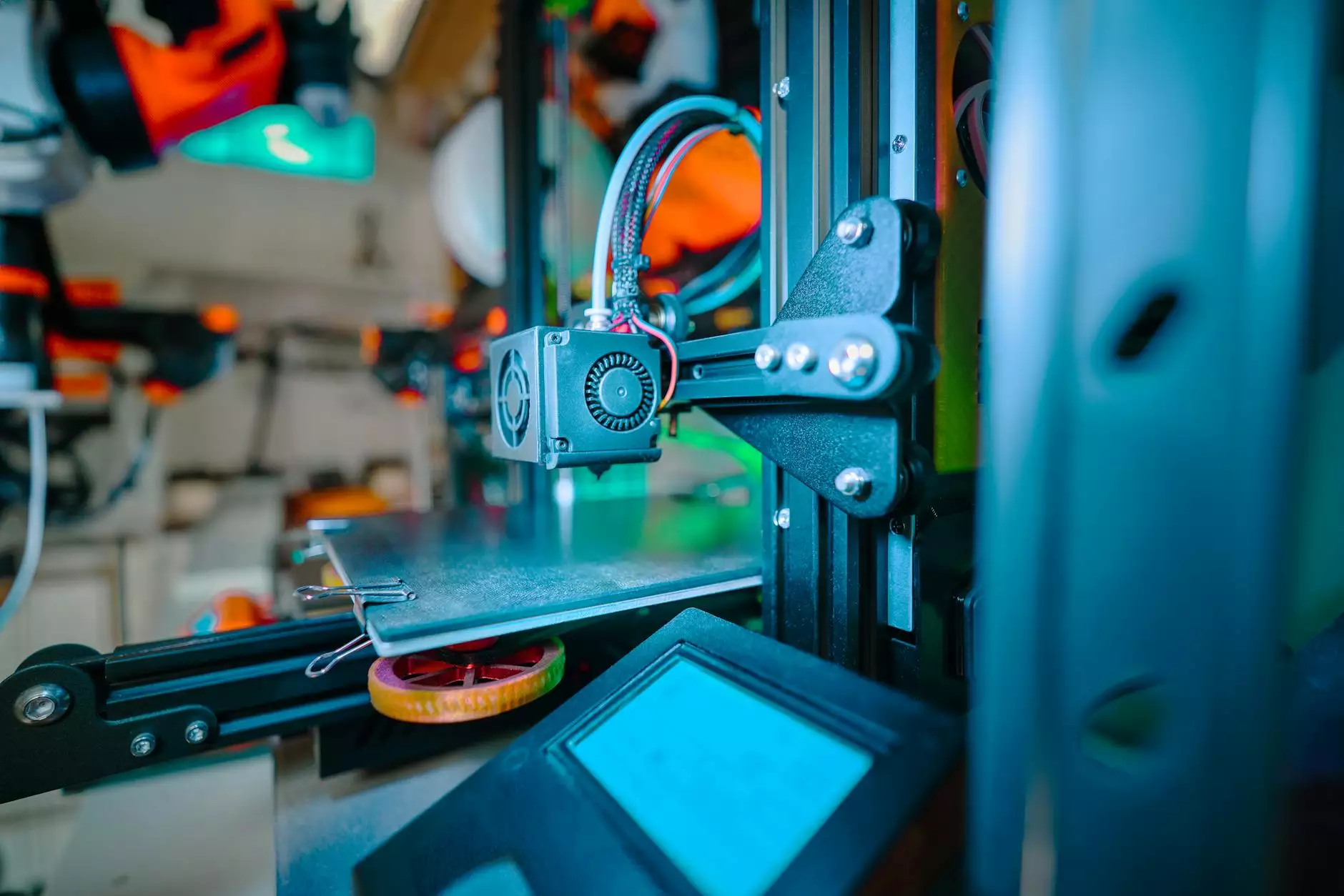

State-of-the-Art Facilities

DeepMould boasts cutting-edge facilities equipped with the latest machinery and tools for precision engineering. From design to production, every step is meticulously managed to ensure the highest quality standards.

Expert Team of Engineers

Our team of skilled engineers and technicians brings a wealth of experience and expertise to every project. Their attention to detail and commitment to excellence ensure that your prototypes are crafted with utmost precision.

Customer-Centric Approach

At DeepMould, customer satisfaction is our top priority. We work closely with our clients to understand their unique requirements and provide tailored solutions that meet and exceed their expectations.

Conclusion

In conclusion, Plastic Rapid Prototypes Factory is a game-changer for Metal Fabricators looking to innovate, accelerate product development, and stay ahead of the competition. With DeepMould's cutting-edge capabilities and customer-centric approach, businesses can unlock a world of possibilities in the realm of rapid prototyping.