Enhancing Your Product Development with **Plastic Prototyping Services**

In today’s fast-paced business world, innovation drives success. Companies in various industries are constantly seeking ways to enhance their product development processes, reduce costs, and stay ahead of the competition. One of the most effective strategies in achieving these goals is through the utilization of plastic prototyping services. In this article, we will explore the ins and outs of these services, their benefits, and how they can transform your business operations.

What is Plastic Prototyping?

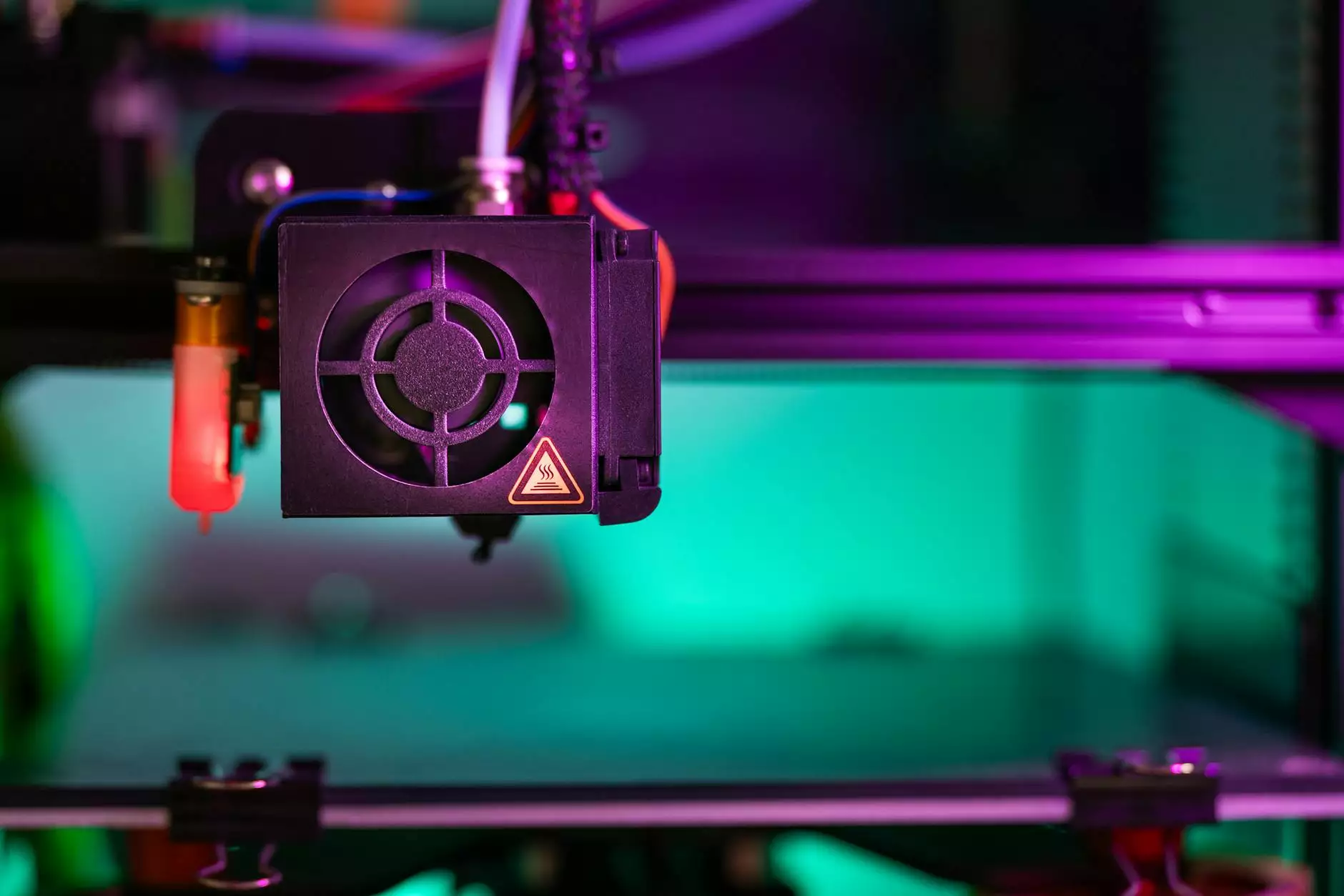

Plastic prototyping refers to the creation of plastic models of products before mass production. This process allows designers and engineers to test, evaluate, and refine their designs with a high degree of accuracy. With advancements in technology, various techniques such as 3D printing, injection molding, and vacuum casting have made plastic prototyping more accessible and effective than ever.

Importance of Prototyping in Product Development

Prototyping plays a crucial role in product development for several reasons:

- Visual Representation: Prototypes provide a tangible model of the product, allowing stakeholders to visualize and assess the design effectively.

- Early Detection of Flaws: By testing prototypes, designers can identify and rectify design flaws before moving to the expensive mass production phase.

- Better Communication: Prototypes serve as a powerful tool for communication between designers, clients, and manufacturers, ensuring everyone is on the same page.

- Cost Savings: Investing in prototyping can substantially reduce the costs associated with product development by reducing the number of iterations required in the design process.

Benefits of Plastic Prototyping Services

Utilizing plastic prototyping services offers numerous advantages that can significantly enhance your business strategy:

1. Accelerates the Development Process

With the speed of technological advancements, time is of the essence. Plastic prototyping services enable rapid prototyping practices that significantly shorten the design and testing phases. Techniques such as 3D printing allow for quick iterations, which helps businesses bring products to market faster.

2. Improves Product Quality

High-quality prototypes lead to better final products. By using plastic prototyping, manufacturers can make precise adjustments based on physical models, leading to improved functionality, usability, and aesthetics in the final product.

3. Facilitates Design Iteration

The ability to iterate designs quickly is one of the greatest advantages of plastic prototyping. Designers can create multiple versions of a product, each with specific alterations, allowing for comprehensive testing and feedback collection. This iterative process ensures that the final design meets the highest standards.

4. Cost-Effectiveness

Though there may be some upfront costs associated with plastic prototyping services, the long-term savings are undeniable. By identifying design flaws early and avoiding costly production errors, businesses can save significant amounts of money.

5. Enhanced Collaboration

Collaboration between teams can sometimes be challenging. However, having a physical prototype facilitates discussions among team members, stakeholders, and clients. This collaborative environment encourages feedback and helps refine the product effectively.

Applications of Plastic Prototyping in Metal Fabrication

In the realm of metal fabrication, integrating plastic prototyping can yield transformative results. Here’s how:

1. Tooling Design

Plastic prototyping services can be used to design and test tooling required for metal fabrication. Prototyping tools can be evaluated for ergonomics, efficiency, and effectiveness before being finalized for production, thereby enhancing the overall fabrication process.

2. Component Testing

Metals can sometimes be costly to experiment with. By producing prototypes of components in plastic, engineers can assess fit, function, and integration with existing systems before proceeding with metal components. This strategy minimizes risk and maximizes utility.

3. Visual Aids for Proposals

When pitching new designs or concepts, having a physical prototype to showcase can make a significant difference. Clients and stakeholders can better understand the vision and potential applications of the proposed metal products.

How to Choose a Plastic Prototyping Service Provider

Choosing the right provider for plastic prototyping services can be daunting. Here are some tips to guide your selection:

- Experience and Expertise: Look for providers with a proven track record and expertise in your industry.

- Technology and Capabilities: Ensure they utilize the latest technologies such as advanced 3D printing and CNC machining.

- Quality Control: Investigate their quality assurance processes to ensure high standards are maintained throughout the prototyping process.

- Customer Support: A responsive customer service team can make a significant difference in addressing your needs and concerns effectively.

Case Studies: Successful Implementations of Plastic Prototyping

Here we highlight a couple of case studies demonstrating the effectiveness of plastic prototyping services in real-world applications:

Case Study 1: Consumer Electronics Company

A leading consumer electronics firm used plastic prototyping to design a new premium smartphone. By creating life-sized models with various aesthetics and ergonomic features, they gathered feedback from focus groups, which aided in refining the product. The final design received excellent market reception and significantly boosted sales.

Case Study 2: Automotive Parts Manufacturer

An automotive manufacturer designed a complex component for a new vehicle model through plastic prototyping services. The team developed several prototypes to evaluate aerodynamics and functional performance before manufacturing the final metal parts. This thorough testing honed the product's design, which enhanced vehicle performance significantly.

Conclusion

In conclusion, the integration of plastic prototyping services offers a range of benefits that can significantly enhance the efficiency and effectiveness of product development, especially in fields like metal fabrication. By investing in quality prototyping, businesses can reduce costs, accelerate time to market, and ultimately improve product quality, leading to greater customer satisfaction and increased profitability.

To discover how our plastic prototyping services at deepmould.net can help your business thrive, get in touch with us today. Our dedicated team is ready to assist you in transforming your product ideas into tangible realities!